Enhanced D-12 Type Design for Maximum Efficiency

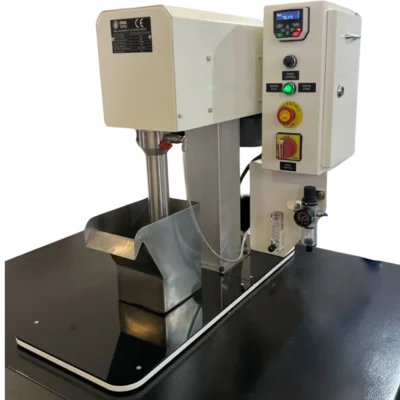

The Ünal Laboratory Flotation Machine, inspired by the widely recognized D-12 type design, has been modernized and upgraded to provide superior usability, precision, and repeatability in flotation testing. It is designed for mineral processing laboratories that require reliable, efficient, and easy-to-use flotation equipment.

Unlike conventional models, our flotation machine eliminates outdated manual controls and introduces advanced electro-mechanical and digital systems, improving ease of operation and accuracy.

KEY UPGRADES & BENEFITS

✅ Enhanced D-12 Type Flotation Technology – Optimized for better usability & precision

✅ Electro-Mechanical Column Control – No more manual crank wheels! Smooth, effortless lifting & lowering via a hand controller

✅ Digital Speed Adjustment – Replaces old pulley & belt system! Set impeller speed with a simple potentiometer (0 – 2880 rpm)

✅ Integrated Air Flow Control – Fine-tune air delivery with adjustable float flowmeters (1 – 12 L/min)

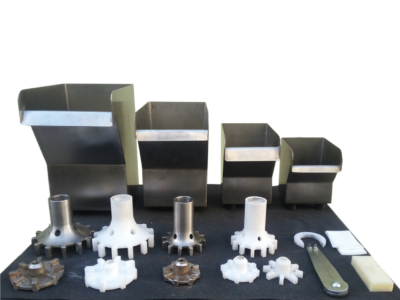

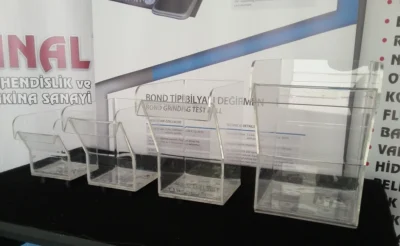

✅ Versatile Flotation Cells – 1, 2, 3, and 4-liter AISI 316 stainless steel or plexiglass cells available

✅ Repeatability & Reliability – Designed for precise, repeatable flotation tests, ensuring consistent experimental results

Sulfide Minerals: Sulfide minerals containing copper, lead, zinc, and molybdenum are enriched by flotation. Examples include:

Sulfide Minerals: Sulfide minerals containing copper, lead, zinc, and molybdenum are enriched by flotation. Examples include: